Introduction

A gas steam boiler is a steam producing heating system. It creates energy by heating water to get steam. It is a heat exchanger that makes steam for outside usage and has a combustion chamber and water container. The several varieties of steam boilers include those that are very small and those that are large for more demanding jobs.

Section 1: Introduction

Section 2: Advantages of Steam Boilers

Section 3: Types of Steam Boilers

Section 4: Maintenance and Repair Issues

Takeaway: If you are looking for a way to heat your home or business, consider using a steam boiler system. It can provide you with efficient heating that is easy to maintain.

gas fired steam boiler

A gas fired steam boiler is a boiler that burns gas to heat water. A typical gas fired steam boiler for industrial process use can be designed to burn natural gas, or any other fuel gases such as propane, butane or even hydrogen.

The most common type of steam generation for industrial processes involves the use of high pressure feedwater and saturated steam at discharge conditions (dryness fraction). In this type of installation, it may also be necessary to provide additional control over the final dryness fraction through an economizer section so as not only maintain positive superheat in the turbine but also avoid condensation within the system itself which would result in increased maintenance costs associated with increased corrosion rates along with adverse environmental effects due to spillage during refueling operations should they occur outside of normal working hours when there are no back up staff available.

What is a gas steam boiler?

A gas steam boiler is a device that generates steam to do work. It is commonly used to heat buildings and generate electricity, but it can also be used in many other applications such as industrial processes.

The boiler is fired by burning natural gas or other fuels using an energy source like coal or wood. The burning fuel heats up water inside of the boiler until it turns into steam—this process is called “boiler superheat” and it’s what makes sure that there are no air bubbles present in your heated water.

A typical gas steam boiler has two main components:

- A hot water storage tank (also called an indirect heat exchanger) for storing hot water during periods of heavy use; and

- A superheater for heating your hot water even further when needed (for example, if someone takes a shower at night).

How much is a gas steam boiler?

How much is a gas steam boiler?

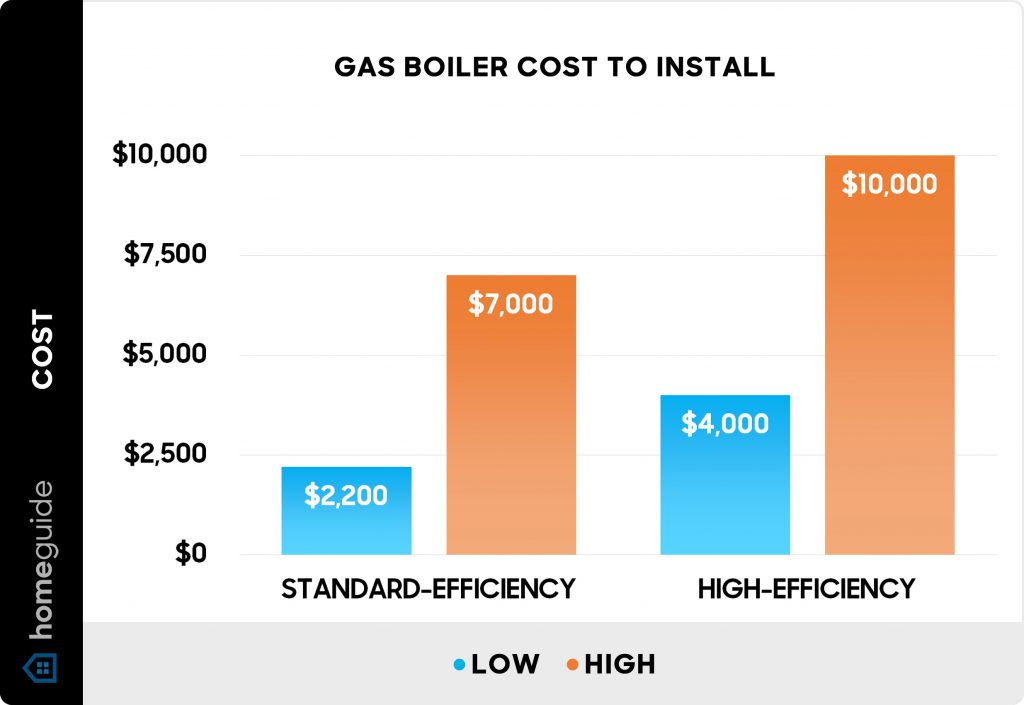

The price of a gas steam boiler will vary depending on the model, size and brand. Usually, smaller boilers are more expensive than large ones. The average price for a medium-sized gas steam boiler is about $4,000-6,500 but the exact cost depends on many factors.

The most important factor affecting the price of your new gas steam boiler is its size and power output capacity which will depend on how much hot water you need in your home or business as well as whether you want to upgrade from an existing electric hot water system (which is usually cheaper).

Is a steam boiler the same as a hot water boiler?

A steam boiler is different than a hot water boiler because it’s more efficient and environmentally friendly. A steam boiler uses heat to turn water into steam, which can then be used for industrial purposes. In contrast, a hot water boiler simply heats water for household use, for example in your bathroom shower or kitchen sink faucet.

The main difference between the two types of boilers is that steam boilers produce purer forms of energy than hot water boilers do—that means you can use them without worrying about pollution levels getting out of control!

What is the life expectancy of a steam boiler?

In general, the life expectancy of a steam boiler is 15 years. This can be affected by several factors and is highly dependent on how well you maintain your boiler. The type of fuel being used also plays a big role in the life expectancy of a boiler as well as its efficiency. For example, if you use liquid propane gas (LPG) instead of natural gas to power your steam boiler, it may have an impact on its overall lifespan because LPG has less BTUs per gallon than natural gas does.

You should also consider where the unit is located when determining how long it will last: if one part of your home gets more use than others do then that area will need to be serviced sooner than others areas would need servicing because wear-and-tear occurs faster with higher levels of usage throughout each day or week depending on what activity takes place there most often (such as cooking meals every night).

How much does it cost to install a steam boiler?

The installation of a steam boiler is not a one size fits all thing. The cost to install a steam boiler depends on the size and complexity of your project. There are many factors that contribute to the price of installing a steam boiler, from building location and type to hardware choices like insulation and piping materials.

gas boiler cost to install chart

Which steam boiler is the best?

The most efficient steam boilers use dry flue gas recuperation, which means they capture heat that would have been lost before it reached the chimney. This also lowers their carbon footprint and reduces your energy bills.

When choosing a steam boiler, you’ll need to decide between gas and electric-powered models. While they’re both effective at producing hot water, there are pros and cons to each:

- Gas-powered units are up to 40 percent cheaper to operate than electric ones (source). However, if the power goes out during a cold snap or on a rainy day when no one’s home for hours at a time, this could be an inconvenience for users who don’t have their own generator.

- Finally, you’ll want to consider how big of an installation job it will be depending on which type of boiler system you choose—whether it’s an entire house installation or just replacing an old system in part of your home such as an apartment building with multiple apartments

Are steam boilers efficient?

Steam boilers are more efficient than gas, oil and hot water boilers. But they’re also more expensive.

Steam boilers produce steam by heating water to its boiling point, which is 100°C (212°F). The steam then passes through a turbine, driving it and generating electricity. The turbine spins a generator that produces electricity; the heat from the remaining steam provides hot water for heating purposes (or in some cases low-temperature industrial processes).

Which boiler is best 2022?

- Gas Steam Boiler:

- The gas steam boiler is a highly efficient and eco friendly boiler, which can be used for commercial purposes. It requires less maintenance and has a long life span. It is designed in such a way that it can work automatically without much human interference. The gas fired steam boiler is useful when there are high demands of power and water supply throughout the day. Gas steam boilers are more efficient than electric boilers due to the low running cost incurred by them, even if they are not on standby mode.*

Which is better steam or hot water heat?

Steam heating is more efficient than hot water heating. The longer the steam is in contact with the pipe, the better it transfers heat and can be used to heat larger areas. Also, there are dual temperature controls on some models, so you can set them to go off when you need them to shut off or run at certain temperatures. This way, there is less risk of scalding yourself while using your unit!

steam gas boiler for sale

Gas steam boiler is a kind of combustion type boiler, which uses gas (such as natural gas, LNG and heavy oil) as the fuel to produce steam. Gas fired steam boiler can be used for many different industrial fields such as chemical engineering, food industry, petroleum refining and metallurgy. The price of gas fired boilers depends on the size and configuration of the furnace itself; however, they can range from $8 per square foot up to $20 per square foot. This means that if you have a large manufacturing plant or factory with multiple boilers running at once, then there could be significant savings in energy costs associated with operating your plant or factory 24/7 throughout the year.

how to install a gas steam boiler

Installing a steam boiler is a job that you can do yourself and save yourself some money. A gas steam boiler will cost you about $5,000 and installation costs around $2,000, so be sure to get an estimate from your local HVAC company before buying the unit.

It’s important to note that installing a gas steam boiler requires high-voltage electricity work, so if you are not qualified to do this type of work then I recommend hiring someone who is licensed with the state as well as insured for their services.

WNS series gas-fired (oil-fired) steam boiler

WNS series gas-fired (oil-fired) steam boiler is used for heating, hot water supply, heating and air conditioning, water supply, steam supply, etc. It has the advantages of high efficiency, low emissions and small volume.

The WNS series gas-fired (oil-fired) steam boiler is mainly used for heating and hot water supply in residential buildings or offices.

SZS series gas-fired (oil-fired) steam boiler

A steam boiler is a device used to generate steam by applying heat energy to water. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including cooking, sanitation and space heating.

Steam is also used in the production of electricity, and in powering ships.

The need to produce useful work from heat energy has led over time to a great variety of designs for boilers and hence their names are varied as well. More efficient designs have tended to replace less efficient ones (for example: coal-fired boilers replaced wood-fired ones).

DHL series coal-fired steam boiler

DHL series coal-fired steam boiler is a kind of boiler with advanced technology, which is widely used for heating and power generation. The characteristics of DHL series steam boilers are as follows:

- Simple structure and convenient maintenance;

- Long service life due to the use of high-quality materials;

- Low investment cost;

- Easy operation and low failure probability;

- Environmental friendly, no pollution when working normally

DZL series coal-fired steam boiler

The DZL series coal-fired steam boiler is suitable for large-scale power generation and industrial heating. It is a kind of high pressure and high efficiency steam boiler with advantages like high combustion efficiency, low thermal inertia and no pollution to the environment.

We have gas steam boiler for sale.

Gas steam boiler is one of the most popular boilers in China. These boilers have many advantages over other types of boilers:

- They produce little or no smoke, so they are very clean and environmentally friendly.

- They generate large amounts of heat and therefore save on electricity costs when compared to oil-fired boilers.

- They are safe because they do not need any flammable materials around them in order to function properly (like propane).

Conclusion

If you are looking for the best gas steam boiler manufacturers, you have come to the right place. We provide complete solutions for any kind of industrial boiler requirements including boiler repair, installation and maintenance services.

To know more about our services, contact us Whatsapp : +8618838908339