Introduction:

A steam boiler is a vital component in many industrial and commercial operations, providing heat and power to buildings, factories, and other facilities. However, for a steam boiler to function properly, it needs a constant supply of water. This is where the steam boiler water feeder comes in. A water feeder is a device that automatically adds water to the boiler as it is needed.

Proper maintenance of the water feeder is crucial for the efficient and safe operation of a steam boiler. In this article, we’ll take a closer look at the steam boiler water feeder, its function, the importance of proper maintenance, and common problems that can arise with water feeders.

Need a new boiler?

What is a Steam Boiler Water Feeder?

auto water feeder for steam boiler

A steam boiler water feeder is a device that automatically adds water to the boiler as it is needed. The water feeder is typically located near the boiler and is connected to the boiler’s water supply line. It is designed to maintain a specific water level in the boiler, typically at the halfway mark between the minimum and maximum water levels.

The water feeder works by measuring the water level in the boiler and adding water as needed to maintain the proper level. It is usually powered by electricity and can be controlled by a switch or a low water cutoff control.

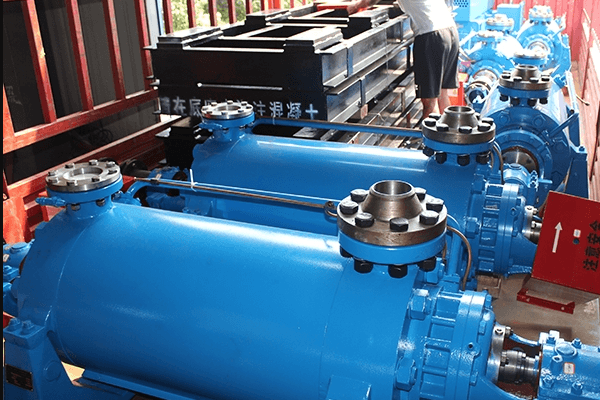

Coal fired hot water boiler system

How does a boiler water feeder work?

120v automatic water feeder for steam boilers

A boiler water feeder is a device that automatically adds water to a steam boiler to maintain the correct water level. It works by using a combination of mechanical and electrical components to control the water level in the boiler.

The water feeder system typically includes a water feed valve, a pressure gauge, and a low water cutoff. The water feed valve is connected to a water supply and is controlled by a float mechanism. As the water level in the boiler drops, the float decreases in buoyancy and opens the water feed valve to add water to the boiler.

The pressure gauge is used to monitor the pressure in the boiler and ensure it stays within safe limits. The low water cutoff is a safety feature that automatically shuts off the fuel supply to the boiler if the water level becomes too low. This helps to prevent overheating and potential explosions.

In summary, the water feeder works by monitoring the water level in the boiler, using a float mechanism to open or close the water feed valve, and using safety features such as pressure gauge and low water cutoff to ensure safe and efficient operation.

Get FREE Boiler Quotes

- ✔Get FREE Local Boiler Quotes today

- ✔Compare The Best Prices

- ✔Save Money On Your New Boiler Today!

Types of Steam Boiler Water Feeders:

gas steam boiler water feeder

There are several types of water feeders commonly used in steam boilers, including:

Open-tank feeders: These are the simplest and most common type of water feeder. They consist of a large tank of water that is connected to the boiler through a pipe. Water is fed into the boiler as needed through a float-controlled valve.

Closed-tank feeders: These water feeders use a pressurized tank to supply water to the boiler. They are typically used in larger boilers and have the advantage of maintaining a consistent water level and pressure.

Automatic feeders: These water feeders use a combination of mechanical and electrical components to automatically control the water level in the boiler. They are typically used in larger boilers and require less manual intervention.

high efficiency gas boiler price

The Importance of Proper Maintenance:

steam boiler automatic water feeder installation instructions

Proper maintenance of the water feeder is crucial for the efficient and safe operation of a steam boiler. If the water feeder is not functioning properly, it can cause a number of problems, including:

- Low water levels in the boiler: If the water feeder is not adding water to the boiler as needed, the water level in the boiler can drop too low. This can cause the boiler to shut down or even damage the boiler.

- High water levels in the boiler: If the water feeder is adding too much water to the boiler, the water level in the boiler can become too high. This can cause the boiler to shut down or even damage the boiler.

- Leaks: If the water feeder is not functioning properly, it can cause leaks in the boiler and the surrounding area, which can be a safety hazard.

Regular maintenance of the water feeder can help prevent these problems and ensure that the boiler is operating efficiently and safely.

What are three major causes of low water in a steam boiler?

natraul gas 12 volt steam boiler water feeder

- Leaks: One of the most common causes of low water in a steam boiler is leaks in the system. These leaks can occur in the pipes, valves, or other components of the boiler, causing water to escape and not be replenished.

- Automatic feeder malfunction: The automatic feeder is responsible for maintaining the correct water level in the boiler, if it malfunctions it could lead to low water levels. This could be due to a malfunctioning valve, a clogged feed line, or a failure of the control system.

- High steam demand: If the steam demand is high, the boiler may be producing more steam than it is able to replenish with water, leading to low water levels. This can happen in situations where the boiler is being used for heavy loads, such as in industrial processes or during a cold winter season.

It’s important to note that, low water levels in a steam boiler can cause damage to the system, reduce efficiency and create safety hazards, so it’s important to address low water issues promptly and to schedule regular maintenance.

Looking for boilers with sophisticated manufacturing, great quality?

Fangkuai boiler can always provide what you want.

Common Maintenance Tasks:

- Checking the water feeder for leaks: Check the water feeder and the surrounding area for any signs of leaks.

- Cleaning the water feeder: Clean the water feeder to remove any debris or buildup that may be preventing it from functioning properly.

- Checking the water feeder’s controls: Make sure that the controls for the water feeder are functioning properly.

- Testing the water feeder: Test the water feeder to make sure it is adding water to the boiler as needed.

- Checking the water level in the boiler: Check the water level in the boiler to make sure it is at the proper level.

Common Problems and Solutions:

- Low water level in the boiler: If the water level in the boiler is too low, it could be caused by a malfunctioning water feeder, a leak in the water supply line, or a malfunctioning low water cutoff control. Check the water feeder, the water supply line, and the low water cutoff control to determine the cause and make repairs as necessary.

- High water level in the boiler: If the water level in the boiler is too high, it could be caused by a malfunctioning water feeder or a malfunctioning high water cutoff control.

Conclusion:

A steam boiler water feeder is a vital component in ensuring safe and efficient operation of a steam boiler. Understanding the different types of water feeders, their functions, and the importance of proper maintenance can help to ensure that your steam boiler is running at peak performance. Regularly inspecting and maintaining your water feeder can help to prevent breakdowns and prolong the life of the system.

Looking for boilers with sophisticated manufacturing, great quality?

Fangkuai boiler can always provide what you want.